Our Services

KWI offers our services to communities to supply healthy, high-quality drinking water to support changing water characteristics, to support population growth and to empower community development.

Water Supply

Engineering, Civil Works, Operation and Maintenance

Problem-Oriented Solutions

Algae Blooming

Algae blooming is an inevitable problem when waterbodies are continuously exposed to nutrients and sunlight. Existing sedimentation tanks are not capable of removing algae. Due to photosynthesis algae cells float to the surface during the day and settle to the bottom of the tank at night.

Recommended Solution: Klaricell

For Drinking Water and Algae Removal

Key Features and Benefits

Stable effluent water quality and turbidity less than 0.5 NTU

Highly efficient algae removal: up to 98%

High sludge concentration (max 5% of solid content) with low chemical consumption

Unaffected by photosynthesis

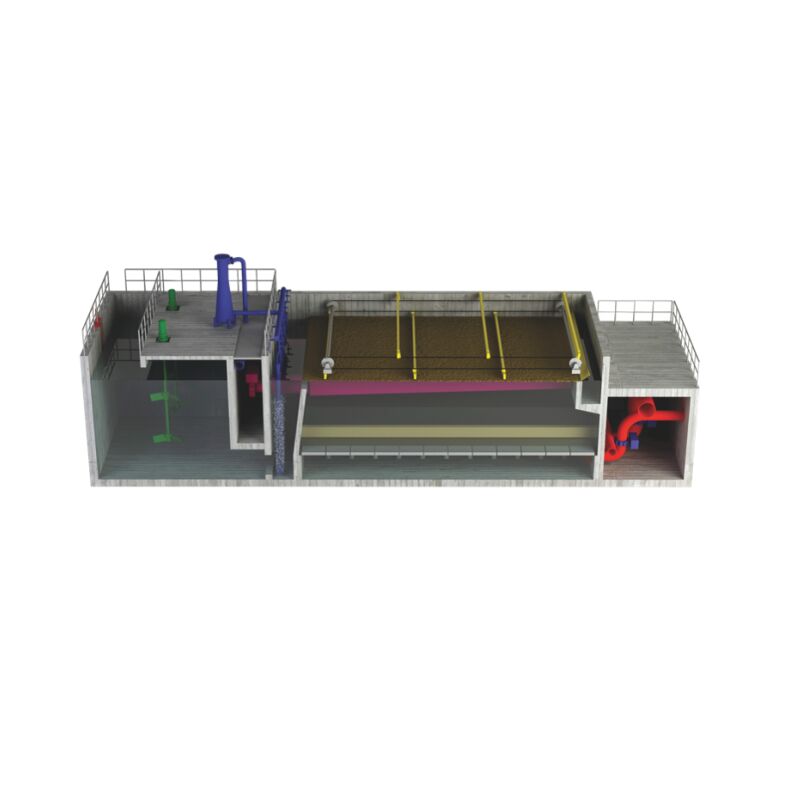

Recommended Solution: Flotofilter

For Drinking Water and Algae Removal

Existing sedimentation tanks can be retrofitted for flotofilters, by keeping and reusing the concrete structure.

Lower capital cost than conventional settlement clarifiers

Hydraulic load: up to 10 m3/(m2·h)

Equipped with surface scraper, sludge concentration up to 3%, which could be dewatered directly

DAF system combined with filtration