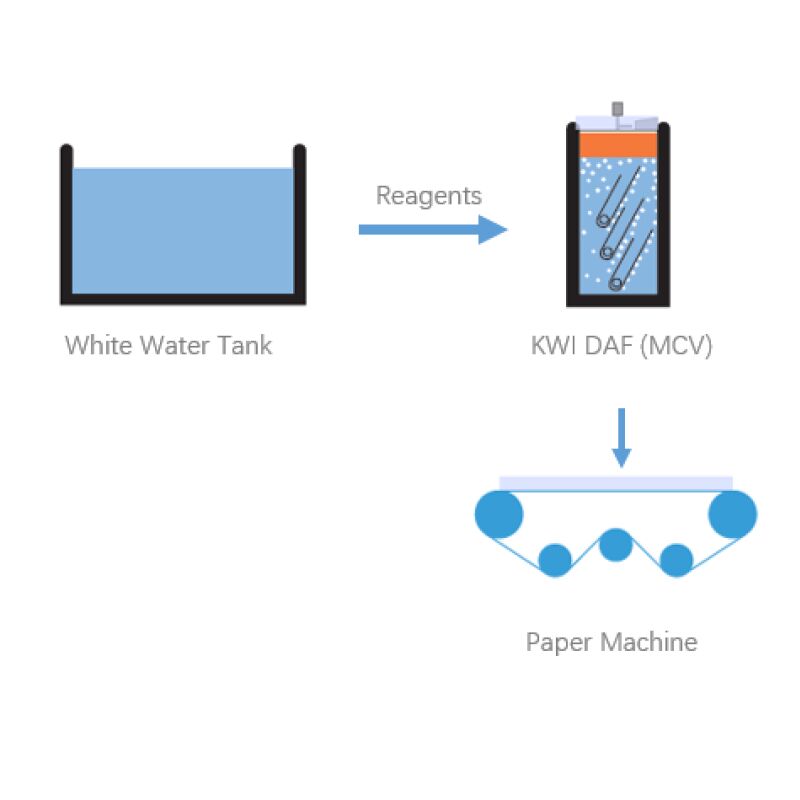

Pulp and Whitewater Recovery

The process of thermo-mechanical pulp (TMP) filtrates allows the recovery of water for re-use which has already been chemically conditioned, and preserve any heat energy in the water. It also allows the recovery of cleaner fiber as dirt is removed from the washing stages.

Our clients in the pulp and paper industry have been using KWI DAF products for over 70 years to remove fiber in process water.

De-inking

In de-inking applications, the ink is removed with the addition of surfactants and the introduction of air by dissolution into the recovered pulp.

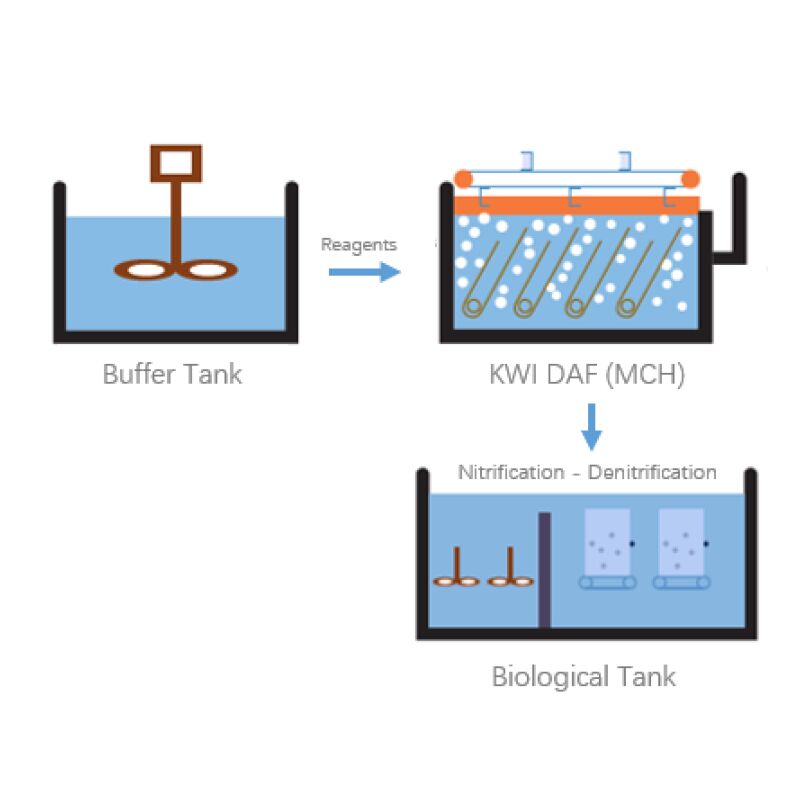

Primary Wastewater Treatment

The DAF is the first choice for primary effluent clarification, for pulp and paper industries. It uses less space than traditional clarifiers, and a single unit can treat up to 2500 m3/h.

With an adjustable scoop and carriage speed, this unit is flexible enough to cope with variations in solids and hydraulic loading, provided the chemical dosing is proportional to the solids and flow.

Secondary Wastewater Treatment

For sludge thickening and clarification applications, a deeper tank is more suited for fragile and weaker flocs, providing the residence time necessary to generate a better sludge blanket or sedimented layer.

Tertiary Wastewater Treatment

The polishing in wastewater can be done using traditional continuous backwash sand filtration. With the backwash facility being the main contributor to the water quality output on a continuous sand filter, it is essential to optimize the backwash parameters (reducing the need for any coagulants).

Our Services

Efficient resource recovery

Reduce water consumption

Achieve discharge standards

Continuous operation

Reliable guarantees

Targeted Recovery

We uncover and target the main parts of your process that are causing loss:

Stock preparation cleaning losses

Wire retention losses

Press losses

Spillages and overflows within the mill

Volatility losses